Product

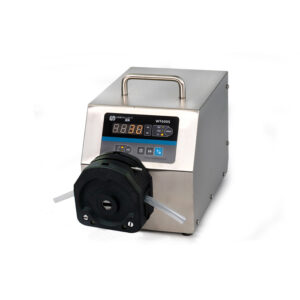

WT300S Large Torque Variable-Speed Peristaltic Pump

Short Description:

Flow range:1.8-3500mL/min

Max number of channel:2

Warranty: 3 years for the peristaltic pump drive

Send Email To Us

WT300S Large Torque Variable-Speed Peristaltic Pump

WT300S-V3 Variable Speed Peristaltic Pump is an upgraded new product launched by Lead

Fluid based on the original WT300S according to market demand. The product uses a

Cortex M3 core processor, runs faster, and has higher speed accuracy of the device. The

display is upgraded from digital tube to LCD display, Chinese and English display, more intuitive. The new deceleration function makes the device run more reliably, and the RS485 communication adds more settings to the MODBUS to meet the requirements of different communication devices. The WT300S-V3 Variable Speed Peristaltic Pump can also be connected

to a thermal printer to print the running parameters of the device. It can also automatically

switch the external analog speed signal type (voltage or current) from the control panel,

which is more convenient and fast.

Features

• LF-LCD-OS Software System, High Definition LCD screen, Chinese and English switching, simple parameter setting,

intuitive status display.

• High quality large torque brushless servo motor drive, precise speed, wide range, stable operation, can achieve high

precision flow transmission.

• Industrial-grade membrane key operation, simple and convenient, strong durability.

• LF-EasyChange universal design, high torque output, can be installed with multiple KZ25 pump heads, KZ25-L pump

heads and GN10 pump heads.

• Start/stop, reversible direction, full speed, adjust speed, state memory (power-down-memory).

• Parameters setting such as running time, interval time, and number of cycles to meet the needs of timing, liquid

packaging, flow testing, etc..

• Speed deceleration and back suction functions, which can effectively prevent liquid dripping when the machine

stops.

• Key lock function to prevent misoperation.

• The pump can be remotely operated through the Lead Fluid APP software, such as start-stop, speed regulation,

timing operation, etc., and has monitoring functions such as shutdown alarm and pipe replacement reminder (optional).

• The pump house is made of stainless steel 304 material, which effectively prevents the corrosion of various organic

solvents and is easy to clean.

• Internal double-deck isolation structure, provide special protection for the circuit system makes it dust-proof and

moisture-proof.

• Super anti-interference feature, wide input voltage range, acceptable for the complex power environment .

• RS485 communication interface, MODBUS protocol is available, easy to connect other equipments.

• Accept various external signal control to start and stop, forward and reverse and speed adjustment, optical coupler

isolation.

• Supports the output of working status signals such as start-stop, forward-reverse, and current speed.

• It can be equipped with an external thermal printer (optional) to print the running parameters in real time.

• Supports accessories such as foot switch, pulse damper, leak detector, etc.

Technical Parameter

Above flow parameters are obtained by using silicone tube to transfer pure water under normal temperature and pressure, in actually using it is effected by specific factors such as pressure, medium etc. Above for reference only.

Dimension

Statement:The final explanation right of above information belongs to Lead Fluid.