Product

BT100F Intelligent Dispensing Peristaltic Pump

BT100F intelligent dispensing peristaltic pumps adopt stepper servo motors, 4.3 inch HD LCD

touch screen display and operation, multiple dispensing modes are available, Through the Lead Fluid APP software, the pump can be remotely controlled and the running status can be moni- tored in realtime.

It is mainly suitable for high-precision transmission and timing and quantitative dispensing of liquids.

Feature

• 4.3 inch color LCD display, intuitive image.

• Touch screen with key operation, convenient and fast.

• LF-Touch-OS software system, efficient and stable, with good human-computer interaction mode, convenient product customiza-

tion and upgrade.

• Working modes: flow rate, time dispensing, volume dispensing, programming dispensing (cycle).

• Five sets of dispensing parameters for volume and time dispensing pre-storage.

• Programming mode supports 30 different quantitative parameter settings for complex control processes.

• Start/stop, reversible direction, full speed, suction function, timed start-stop.

• Accurate flow control and display, microstep algorithm to ensure the dispensing accuracy of different settings.

• Wizard flow calibration function, easy to use.

• Unique back suction function to prevent liquid drips.

• Support for serial print parameters and data.

• Intelligent temperature control function, automatically adjusting the heat according to the environment, so that the device is always in the best state.

• WIFI control function, remote operation can be realized through the Lead Fluid APP software, and has monitoring functions such as shutdown alarm and reminding to replace the pump tube.

• External analog adjust speed , external control start-stop ,reversible direction, dispensing, external signal physical isolation.

• RS485 communication interface, MODBUS protocol is available, can set up communication parameters, convenient to connect various of control equipments.

• Open multiple control parameters , suitable for OEM custom applications.

• The circuit board is sprayed with three anti paint technology to achieve the effect of dustproof and moisture-proof.

• Super anti-interference feature, wide input voltage range, acceptable for the complex power environment.

• Innovative stainless steel housing, easy to clean, effectively prevent the erosion of various organic solvents.

Technical Parameter

BT100F Applicable Pump Head and Tube, Flow

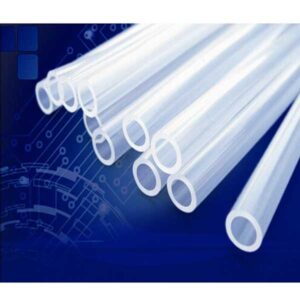

Above flow parameters are obtained by using silicone tube to transfer pure water under normal temperature and pressure,in actually using it is effected by specific factors such as pressure, medium etc. Above for reference only.

Dimension(mm)

Statement:The final explanation right of above information belongs to Lead Fluid.

-.webp)

-.webp)

.webp)